Introduction of cover plates plastic mold

At present, municipal road engineering, tunnel engineering, subway engineering construction above, in addition to the use of ductile iron products , most also use concrete cover plate , concrete has the characteristics of rich raw materials, low price, simple production process of precast concrete cover plate. At the same time, concrete also has high compressive strength, good durability, precast concrete cover plate strength grade range is wide, so that its use range is very wide. Not only in all kinds of civil engineering, but also in the shipbuilding industry, machinery industry, Marine development, geothermal engineering, etc., Concrete cover plate is also an important material.

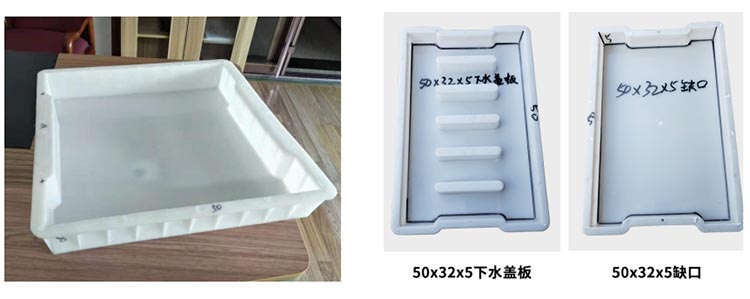

With the increase of demand for concrete cover plates, many factories and a small number of buyers began to produce , because the technical requirements are not high, only need to make molds, it can quickly produce finished products. Some self-use and small-scale buyers will choose their own production, which requires the purchase of the corresponding size of the mold in accordance with the demand. For the production of concrete cover plates, the main molds in the market are steel molds, aluminum molds and plastic molds. The most commonly used molds are plastic molds, which are popular because of their common raw materials, low cost, light weight and low transportation cost.