Classification of scaffolding fasteners

Fasteners are the core components of the coupler-type steel pipe scaffolding (also known as the predecessor of “traditional scaffolding” or “bowl-buckle scaffolding”). Their quality and correct use are directly related to the safety of the entire scaffolding.

1. Classification by function and purpose (this is the most core classification method)

According to the national standard “Steel Tube Scaffolding Couplers” (GB 15831-2006), they are mainly divided into three basic types:

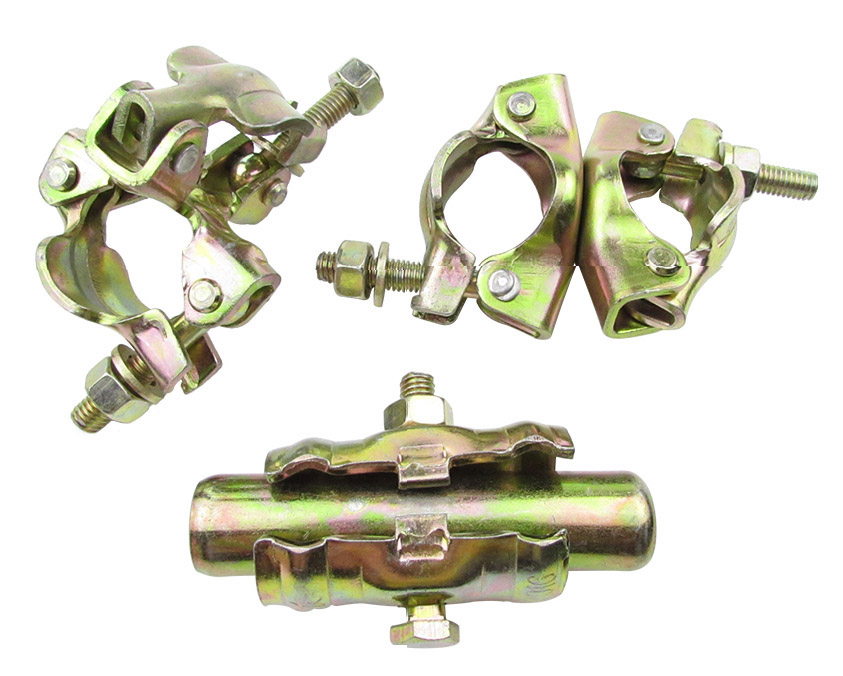

(1) Right angle coupler

- Use: Used to connect two vertically intersecting steel pipes (for example, connecting a vertical pole to a horizontal pole).

- Function: This fastener is the most commonly used and critical load-bearing component of all fasteners, primarily transmitting vertical loads and resisting horizontal forces.

- Appearance: Cross-shaped.。

(2) Swivel Coupler

- Use: Used to connect two parallel or oblique steel pipes.

- Function: Primarily used for connecting scissor braces, diagonal braces, and toe braces, but can also be used for joints requiring angle adjustment. It allows two steel pipes to be rotated and locked at any angle between 0° and 360°.

- Appearance: Appears in a straight line shape, but the movable parts can rotate.

(3). Fixed Coupler for Scaffolding

Use: Used for butt-jointing two steel pipes.

Function: Specifically designed for extending vertical or horizontal poles to ensure axial force transmission.

Appearance: Shaped like a “I” with a central protrusion and groove for aligning steel pipes.

2. Classification by surface anti-corrosion treatment method

1. Galvanized fasteners: These are hot-dip galvanized or electroplated. They offer the best corrosion and rust resistance, excellent durability, and are suitable for humid environments and high-standard projects. However, they are more expensive.

2. Spray-coated fasteners: These are sprayed with an anti-rust paint (usually red, yellow, or blue). While inexpensive, the paint film can easily break and rust, requiring regular maintenance.

3. Black fasteners: These are not treated with any anti-corrosion treatment and are very prone to rust. They are not recommended.

Summary and Safety Points

| Type | Main Applications | Key Features |

| Right angle coupler | onnect vertically crossed steel pipes | The largest amount is used for connecting vertical poles and horizontal poles. |

| Swivel Coupler | Connect steel pipes at any angle | Used for scissors support and diagonal rod |

| Fixed Coupler for Scaffolding | Connect two steel pipes in the same direction | Used to extend vertical poles or horizontal poles |

Tips for safe use:

- Mixing is strictly prohibited:Fasteners from different manufacturers and batches may not be fully compatible due to size and performance differences, so mixing should be avoided.

- Scrap criteria:Fasteners exhibiting cracks, deformation, or thread stripping must be immediately scrapped and strictly prohibited from further use.

- Torque requirements: The tightening torque for fastener bolts should reach 40 N·m to 65 N·m to ensure anti-slip bearing capacity. Tightness can be checked with a torque wrench.

- Gray cast iron fasteners are prohibited in the main structure:For the main load-bearing structure of the scaffolding, malleable cast iron fasteners or high-quality steel plate stamping fasteners that meet national standards must be used.