Specification requirements for scaffold erection

First of all, according to different scaffolds, the safety specifications in the specific construction process are also different. General scaffolds can be divided into floor type scaffold, attached lifting scaffold, cantilever scaffold, portal scaffold, etc.

1. Floor type scaffold

When the floor type scaffold is used as the foundation of the tower, the ground must be flat and solid, there must be no ponding in the erection site, and drainage ditches or other drainage measures should be set outside and around the scaffold.

It is necessary to have enough bearing capacity. The bearing capacity of the supporting pole base plate should meet the requirements. The bottom elevation of the base should be 50-100 mm higher than the natural floor.

2. Attached lifting scaffold

During the installation of attached lifting scaffold, it is necessary to pay special attention to whether the equipment has four devices, namely, full-automatic fall prevention device, anti overturning device and synchronous control or load control device. It is also necessary to judge whether its technical performance meets the specification requirements.

The operation surface at the bottom of the scaffold must be covered with scaffold board, and there must be no gap, probe board and springboard. There must be horizontal safety net protection facilities under the scaffold, or bamboo plywood under the scaffold board. The gap between the scaffold body and the structure is provided with an openable flap protection at the bottom side of the scaffold and no two floors above, so as to ensure the vertical protection circle, which can effectively prevent the falling of small objects such as rice reinforced head, fastener and concrete block from injuring people.

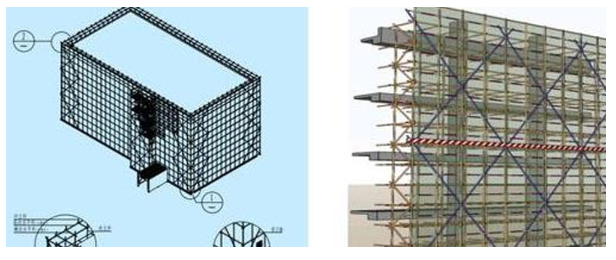

3. Cantilever scaffold

Cantilevered scaffold is mainly through the setting of cantilevered beam at the edge of the building, through which all or part of the load of the scaffold is transferred to the building structure, and the frame body is firmly tied with the building through tie pieces to meet the construction needs. In the specific construction process, I-steel, channel steel and other section steel above 16 are usually used as infrastructure, and rebar is strictly prohibited.

When using No. 16 I-beam, the reinforcement head of ¢ ≥ 25 should be welded at the place 100 ¢ away from the front end of the cantilever beam to fix the upright pole (prevent the upright pole from shifting). The welding must be fully welded (spot welding is not allowed) to ensure the welding quality. The reinforcement head is 200 ¢ higher than the I-beam. Secondly, the I-beam must be fully painted with yellow antirust paint.

4. Portal scaffold

The portal steel pipe scaffold needs to comply with the current industry standard “technical code for safety of portal steel pipe scaffold in building construction” (hereinafter referred to as “code”) jgj128.

The portal steel pipe scaffold is mainly composed of vertical pole, horizontal pole and reinforcing pole. The pole foundation of the scaffold body shall meet the requirements of the project scheme, and shall be flat and practical with drainage measures; the base plate and vertical pole base shall be set at the bottom of the scaffold body, and the sweeping pole of the scaffold body shall meet the requirements of the code.

Generally, the angle between the diagonal bar of cross bracing and the ground should be between 45 ° and 60 ° and fixed with rotary fastener and vertical bar, the setting of cross bracing and cross bracing, etc., and the vertical deviation of vertical bar of portal frame should meet the specification requirements.