The Development History of Composite Material Well Covers

Development history

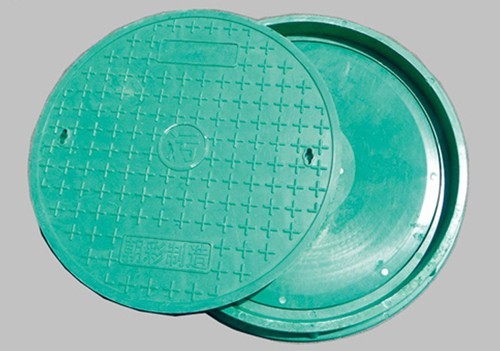

(1) Its strength is second only to that of stone plastic manhole covers. Can carry vehicles weighing over 40 tons.

(2) Its comprehensive performance is between that of stone plastic manhole covers and concrete manhole covers, superior to concrete; Can be applied in situations where there is a high demand for manhole cover technology.

(3) Its outstanding advantage is that it does not use steel skeleton reinforcement, but instead uses fiberglass composite reinforcement, which belongs to GRC type products. Therefore, it has the advantage of being unaffected by the continuous rise in steel prices. Due to its absence of any iron, it is more anti-theft than stone plastic and fiber reinforced concrete manhole covers.

(4) Its curing speed is several times faster than fiber reinforced concrete, and it can be demolded in 8 hours. If produced in three shifts, it can be demolded three times in 24 hours. Although the amount of mold used is more than that of stone plastic, it is only about 1/6 of that of fiber reinforced concrete manhole covers, which can also reduce mold investment. Annual production of 10000 sets of manhole covers only requires 10 sets of molds.

(5) Composite manhole covers are ideal, advanced, and incomparable to other molds such as rubber molds, plastic molds, and fiberglass molds.

(6) The composite manhole cover has been continuously improved and updated, and all indicators have exceeded the industry standards of the Ministry of Construction, basically meeting the national standards